Linear slides are precision-controlled devices that provide pushing, pulling or positioning action along linear planes. They carry out linear motion, which is why they are named linear slides. Read More…

Del-Tron is a linear slide manufacturer/distributor of ball bearing slides, crossed roller tables, roller slides, multi-axis positioning stages, xy tables, motor-ready lead screw stages & crossed roller rail sets.

When describing Tusk Direct, a linear slide distributor, products such as linear motion components, roller tables, ball & crossed roller slides, dovetail slides, bushings, multi-axis positioners & motor ready lead screw actuators, come to mind.

Isotech is a distributor of precision linear motion components: air cylinders, linear actuators, linear slides, ball slide assemblies, crossed roller slide assemblies, re-circulating ball slide guides. We can supply standard or high precision products in either English or metric, all with the convenience of on-line ordering. Our parts are ready for installation right out of the box.

More Linear Slide Manufacturers

Applications

Linear slides, also referred to as linear motion bearings or linear guideways, are engineered to provide unrestricted linear motion and precision control within a wide variety of machinery and automation systems. These versatile components offer accurate guidance and robust support mechanisms, ensuring seamless, repeatable, and exact movement critical for countless modern industrial and manufacturing processes.

Thanks to their automated, precision-controlled design, linear slides are highly suitable for an expansive range of linear motion applications. Whether facilitating small-scale operations or managing the demands of heavy-duty industrial automation, they are foundational in environments such as clean rooms, robotics (including robotic welding and assembly), laboratory instrumentation, precision assembly of optical and electronic components, automated packaging lines, and CNC machining operations. Their reliability and accuracy make them indispensable in industries that require uncompromising precision and efficiency.

Linear slides are vital in a multitude of sectors, including but not limited to: aerospace, automotive manufacturing, chemical processing, commercial food production, healthcare and medical device engineering, laboratory automation, semiconductor manufacturing, electronics, textile production, and high-speed printing. Their adaptability and precision make them a preferred choice for engineers and designers seeking dependable linear motion solutions for both custom and off-the-shelf machinery.

The History of Linear Slides

The concept of linear motion is far from new—humans have utilized forms of linear slides for over two millennia. Archaeological discoveries, such as a Roman shipwreck from 40 B.C. containing wooden rolling bearings, confirm their ancient origins. However, it is likely that the principle predates even these finds. Egyptian hieroglyphs and tomb illustrations depict early linear slides crafted from tree trunks placed under sleds, lubricated with water or oil, and primitive plain bearing runners used with hand-operated drills. These innovations represent the earliest attempts at reducing friction and facilitating smooth linear movement in basic tools and transport devices.

During the Renaissance era, technological curiosity flourished. Leonardo da Vinci incorporated ball bearings into his helicopter designs, a concept that would influence future developments. Shortly after, Italian engineer Agostino Ramelli sketched early concepts of roller and thrust bearings. In the 1600s, Galileo Galilei advanced Ramelli’s work by proposing caged rollers or balls within enclosures—a method to minimize friction and wear. Yet, practical implementation was delayed until John Harrison adopted Galileo’s ideas in his H3 marine timekeeper, employing caged roller slides to enhance accuracy and reliability.

With the onset of the Industrial Revolution, the need for reliable linear motion components surged. In 1794, Philip Vaughan secured the first patent for a ball bearing design—featuring a ball running along a groove within an axle assembly—to improve transportation and machinery. This innovation was soon followed by the radial ball slide in 1869 and the tapered roller bearing in 1898. By 1883, engineers had devised advanced methods for grinding and milling uniform bearing balls, ushering in an era of precision manufacturing for watches, clocks, water mills, and vehicle wheel and axle assemblies.

The 20th century witnessed exponential growth in linear bearing technology. In 1907, Sven Wingquist invented the self-aligning linear ball bearing, revolutionizing machine tool accuracy. Erich Franke’s wire race bearing in 1934 and Bud Wisecarver’s v-groove bearing guide wheels in 1972 further expanded application possibilities. The early 1980s saw Robert Schroeder of Pacific Bearings introduce bi-material plain bearings, combining a metal shell with a Teflon-based liner for reduced friction and maintenance.

Today, the linear slide industry is deeply influenced by advancements in robotic automation, mechatronics, and smart manufacturing. High-performance linear guideways are integral to precision dental drills, optical alignment systems, semiconductor fabrication equipment, and even space exploration robots like the Mars Rover. As automation and industrial digitization evolve, linear slide technology continues to push the boundaries of accuracy, reliability, and application versatility.

Design

Production Process

The manufacturing of linear slides involves several essential processes designed to ensure strength, precision, and smooth motion. Key production steps include extrusion, shape rolling, drawing, and forging. Through these methods, manufacturers create foundational components such as the stationary base, carriage (or moving table), and the linear rail—the guiding element fitted with high-precision bearings. Rails may be specified with flat or rounded, polished surfaces, depending on the application’s accuracy and load-bearing requirements.

Following component fabrication, assembly begins by attaching the carriage to the stationary base along the linear rail. This configuration enables the carriage to glide smoothly and precisely over the full length of the base, supported by a system of ball bearings, rollers, or plain bearings. For applications that demand high speed or automation, manufacturers may integrate stepper motors, servo motors, or linear actuators—enabling programmable, automated movement and advanced control schemes.

Looking for more details on linear slide manufacturing processes? Get answers to common questions:

- How are precision linear rails manufactured to tight tolerances?

- What are the differences between ground and rolled linear guideways?

- How do manufacturers ensure smooth, low-friction travel in high-speed linear actuators?

Materials

Choosing the right materials is critical for designing linear systems that meet demanding performance, durability, and environmental requirements. The most common materials for linear slides are cast iron, aluminum, and stainless steel, each offering distinct advantages:

- Cast Iron: Renowned for exceptional strength, rigidity, and wear resistance. Ideal for heavy-duty linear motion applications, CNC machinery, and environments subject to high loads or impacts.

- Aluminum: Lightweight yet structurally robust, aluminum provides excellent resistance to corrosion and deformation under moderate loads. Frequently chosen for laboratory automation, lightweight transport, and equipment where weight is a concern.

- Stainless Steel: The preferred material for linear slide systems operating in corrosive, humid, or sanitary environments—such as food processing, medical equipment, and clean room automation. Stainless steel’s resistance to rust ensures longevity and minimal maintenance.

Material selection may also factor in surface treatments (like hard anodizing or chrome plating) to further enhance corrosion resistance, reduce friction, or increase wear life. Advanced polymer and ceramic liners are also available for specialized linear bearing applications where ultra-low friction or chemical resistance is necessary.

Design and Customization Considerations

Before designing a linear slide system, manufacturers must carefully evaluate a range of application-specific criteria:

- Operating environment (clean room, chemical exposure, temperature extremes)

- Expected cycle frequency and speed requirements

- Nature and dimensions of loads to be moved

- Precision and repeatability requirements

- Spatial constraints and mounting orientation

- Power source (manual, motorized, pneumatic, or hydraulic drive)

- Compliance with industry standards (ISO, DIN, JIS, etc.)

Manufacturers offer a wide range of customization options for linear slides, tailoring dimensions such as rail width and length (measured in millimeters), shaft style (round, square, or custom profiles), flange type, load capacity, friction characteristics, resistance elements (such as built-in wipers or seals), and saddle length. Specialized accessories—like covers, shields, slide blocks, and integrated lubrication systems—can be specified to improve performance in harsh or highly regulated environments.

Features

Linear slides are engineered for simplicity and reliability. Their basic structure includes a fixed rail or base—typically housing the bearing system—onto which a carriage, platform, or moving table is mounted. This compact assembly enables precise, controlled linear motion with exceptionally low friction and minimal energy consumption. The result is a system capable of delivering smooth, repeatable travel—ideal for automated motion control, material handling, and positioning systems.

To protect sensitive bearing surfaces from contaminants like dust, debris, and moisture, manufacturers often integrate shields, bellows, or covers. These protective elements ensure consistent performance and extend the lifespan of the linear motion system even in demanding industrial settings.

Many linear slides operate without motors, relying on inertia and manual force. In such systems, higher inertia requires greater torque—the rotational force necessary to initiate movement. For advanced or automated applications, slides can be fitted with linear motors or actuators, enabling programmable, high-speed, and high-precision motion powered by AC or DC electric motors, or even pneumatic or hydraulic drives. Despite these options, the core value of linear slides remains their ability to deliver controlled, precise, and reliable linear movement.

Types

Linear slides are available in two primary categories: motorless and motorized slides. Each type offers unique advantages and is suited to specific use cases:

- Motorless Slides: Best for applications requiring reliable manual movement or low-maintenance operation. These include ball bearing slides, drawer slides, roller slides, and telescopic slides—ideal for furniture, cabinetry, industrial enclosures, and heavy-duty material handling.

- Motorized Slides: Designed for programmable, automated movement with precise speed and position control. Examples include XY tables, roller tables, machine slides, lead screw-driven slides, and motorized dovetail slides—used extensively in robotics, laboratory automation, CNC machining, and semiconductor processing.

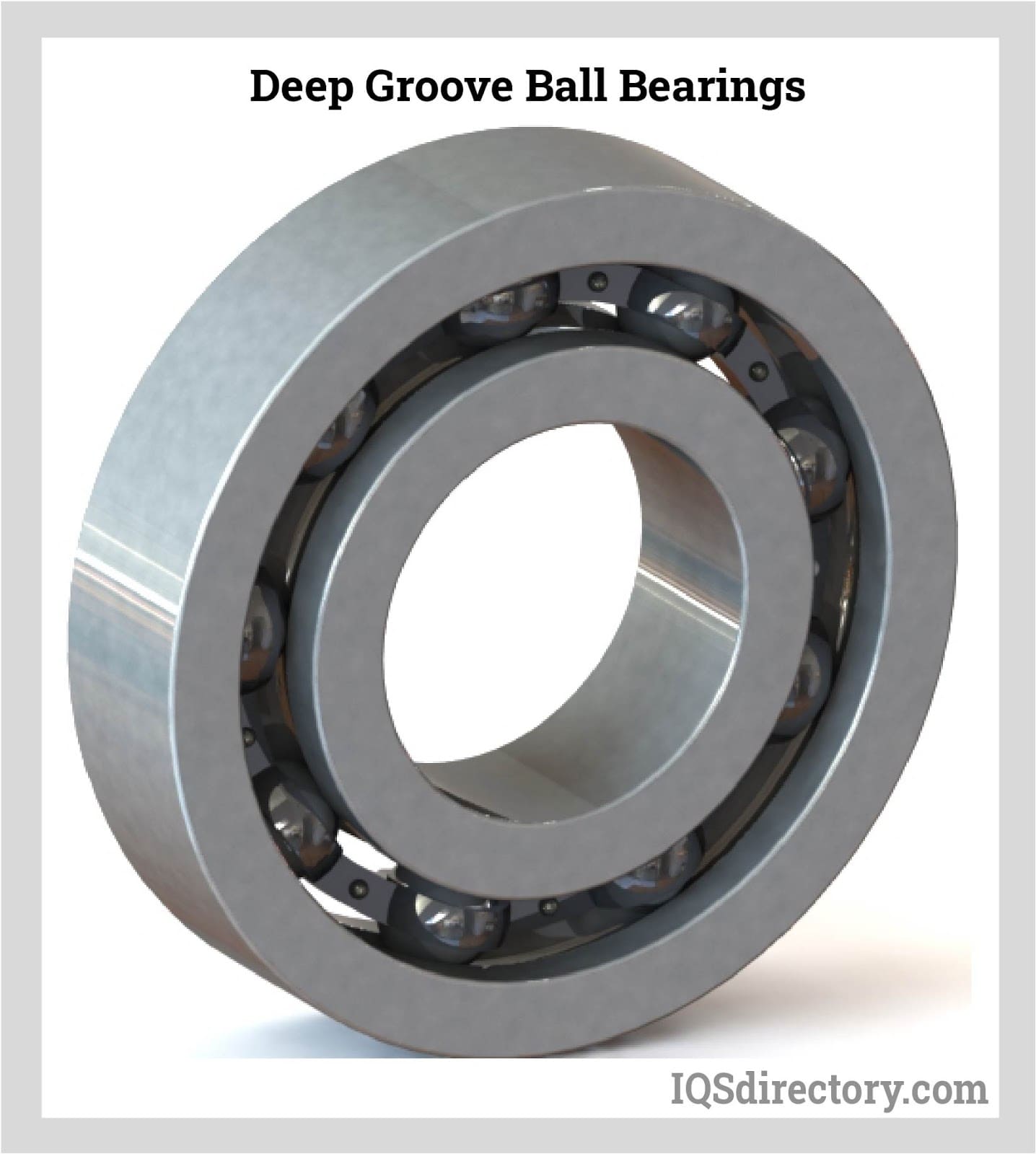

Ball Bearing Slide

Ball bearing slides (or “ball slides”) feature self-lubricating ball bearings arranged around precision-ground shafts. This design ensures smooth, low-friction, and reliable linear motion, making them the most widely used type in both manual and automated systems. Their compact form factor and high load capacity make them ideal for electronics, laboratory instruments, and precision assembly.

Drawer Slide

Drawer slides are engineered for easy, quiet, and smooth opening and closing of drawers in furniture, tool cabinets, and industrial storage systems. They are available in side-mount, under-mount, and center-mount configurations to accommodate various installation requirements.

Roller Slide

Roller slides employ perpendicular rollers for movement, creating a line of contact (as opposed to the point contact of ball bearings). This allows them to support heavier loads with reduced stress and minimal friction, making them suitable for machine tool tables and high-load transfer systems.

Telescopic Slide

Telescopic slides are composed of nested, concentric rails that slide within each other, enabling complete extension and retraction. These are commonly used in applications where space-saving and full-extension access are required, such as industrial drawers, server racks, and heavy equipment panels.

XY Table

Motorized XY tables combine two perpendicular linear slides to allow movement in both X and Y axes. Integrated with bearing-based linear motion systems and typically driven by stepper or servo motors, XY tables are essential for pick-and-place robotics, laser engraving, and automated inspection systems.

Machine Slide

Machine slides incorporate linear actuators and are designed for integration with CNC machines, lathes, and milling centers. Many feature built-in cleaning mechanisms (such as machine wipers) that remove debris from rails, ensuring optimal performance and longevity in abrasive environments.

Lead Screw

Lead screw slides use a threaded shaft and nut to convert rotary motion into precise linear movement, without relying on ball bearings. Their self-locking characteristics make them suitable for vertical positioning, laboratory automation, and applications where holding force is critical and back-driving must be prevented.

Dovetail Slide

Dovetail slides feature a stationary base and a saddle or flaring tendon. Known for their durability and ability to dampen vibrations, dovetail slides are the preferred choice for heavy-duty machining, grinding, and applications requiring extended travel distances and rugged performance.

Advantages of Linear Slides

Linear slides deliver a host of valuable benefits to equipment designers, OEMs, and end users alike. Key advantages include:

- Energy Efficiency: Particularly in motorless models, linear slides require minimal force or torque for movement, reducing power consumption and operational costs.

- Low Friction & Smooth Operation: The use of precision bearings and advanced materials ensures exceptionally low friction, resulting in quiet, smooth, and accurate motion.

- High Load Capacity: Despite their compact form, linear slides can support substantial weights, ideal for heavy-duty industrial applications.

- Minimal Maintenance: The simple design—with few moving parts—means less wear, fewer breakdowns, and lower maintenance requirements compared to alternative motion systems.

- Precision & Repeatability: Linear slides are engineered for high accuracy, making them essential for automated machinery, laboratory equipment, and any process demanding repeatable, reliable linear movement.

- Versatility: Available in a wide range of sizes, load ratings, and configurations, linear slides can be customized or selected off-the-shelf for nearly any application or industry.

Accessories

To further enhance the performance, durability, and versatility of your linear guideway system, a variety of accessories are available. These include:

- Wipers & Seals: Keep contaminants away from bearing surfaces, prolonging life and reducing maintenance.

- Lubricants & Lubrication Systems: Minimize friction and wear for smoother operation and extended longevity.

- Slide Guide Mounting Hole Caps & Covers: Protect mounting points from dust and debris.

- Clamps, Block Stopper Plates, and Linear Locks: Secure the carriage in position for safety or precise alignment.

- Roller Tables & Height-Adjusting Blocks: Customize slide height or provide additional stability for specialized machinery.

- Mounts & Stopper Bolts: Enhance installation flexibility and prevent overtravel.

Looking for accessory recommendations? Ask our experts: “Which linear slide accessories are essential for clean room automation?” or “How can I improve the lifespan of my linear rails in corrosive environments?”

Proper Care for Linear Slides

Ensuring the longevity and optimal performance of your linear motion system requires regular maintenance and diligent care. Linear systems are exposed to diverse operating environments and challenges—such as moisture, dust, chemicals, and mechanical impacts—that can accelerate wear or lead to premature failure if not addressed.

Key maintenance tips include:

- Regular Bearing Replacement: Bearings are the most susceptible to wear. Replace them at recommended intervals to prevent operational issues.

- Environmental Protection: Maintain a clean operating environment. Use covers, shields, or bellows to protect linear bearings from dust, debris, and moisture.

- Proper Lubrication: Apply appropriate lubricants based on manufacturer recommendations and application environment. Increased friction, especially in shielded systems like dovetail slides, can be mitigated with additional lubrication.

- Routine Inspection: Check for misalignment, unusual noises, or visible wear. Early detection of issues can prevent costly downtime.

For slides equipped with machine wipers or automatic cleaning mechanisms, ensure these components are functioning correctly. While they are highly effective at removing debris from rails, they may increase friction in certain slide types. Monitor system performance and adjust maintenance routines as needed to sustain optimal operation.

Finding the Right Manufacturer

With myriad linear slide manufacturers and suppliers in the market, choosing the right partner for your project can be overwhelming. The difference between high-performance, reliable linear motion systems and subpar alternatives often comes down to the expertise, quality assurance, and customization capabilities of the manufacturer.

To simplify your decision-making process, we have curated a comprehensive list of reputable manufacturers, each with detailed profiles highlighting their strengths, product portfolios, and customer testimonials. This resource empowers you to compare options and confidently select a supplier capable of meeting your unique requirements.

How to choose the best linear slide manufacturer:

- Start by identifying your specific needs: application type, required load and precision, environmental conditions, preferred materials, and compliance with industry standards.

- Consider factors such as lead time, budget, customization options, and after-sales support.

- Review manufacturer profiles, product catalogs, and references—pay attention to areas of specialization, engineering support, and track record in similar applications.

- Shortlist three or four manufacturers and contact them directly to discuss your project in depth. Ask about customization capabilities, quality control processes, and warranty terms.

- Compare responses and proposals, weighing not only pricing but also overall value, responsiveness, and technical expertise. Select the manufacturer that best aligns with your goals and inspires confidence in their ability to deliver a high-quality solution.

Investing in the right linear slide system can dramatically improve the efficiency, precision, and reliability of your machinery. Whether you need a standard off-the-shelf component or a custom-engineered solution, choosing a trusted manufacturer is the first step toward achieving optimal performance and long-term value.

What are linear slides and where are they used?

Linear slides, also known as linear motion bearings or linear guideways, are engineered to provide precision-controlled, unrestricted linear motion in a range of machinery and automation systems. They are essential in environments such as robotics, laboratory equipment, CNC machining, packaging lines, clean rooms, and many manufacturing applications requiring accurate, repeatable movement.

What are the main types of linear slides?

Linear slides come in two primary categories: motorless slides (including ball bearing slides, drawer slides, roller slides, and telescopic slides) and motorized slides (such as XY tables, roller tables, machine slides, lead screw-driven slides, and motorized dovetail slides). Each type offers specific benefits suitable for different applications in industrial, commercial, or laboratory settings.

What materials are commonly used to manufacture linear slides?

The most common materials for linear slides are cast iron, aluminum, and stainless steel. Cast iron is valued for strength and durability in heavy-duty applications. Aluminum is lightweight and corrosion-resistant, suitable for laboratory or portable systems. Stainless steel is preferred for environments requiring sanitation or corrosion resistance, like food processing and medical equipment.

How are precision and smooth movement achieved in linear slides?

Precision and smooth movement are achieved through high-quality manufacturing processes such as extrusion, rolling, drawing, and forging, followed by careful assembly. The use of precision-ground rails and ball, roller, or plain bearings reduces friction and ensures accurate, low-resistance linear movement. Integrated lubrication systems and protective features further enhance performance and longevity.

What maintenance is required for linear slides?

Regular maintenance includes replacing worn bearings, keeping the environment clean, applying proper lubrication as recommended, and inspecting for misalignment or wear. Using protective shields, covers, or wipers also extends life by keeping contaminants away from sensitive bearing surfaces.

What are some advantages of using linear slides?

Linear slides offer energy efficiency, low friction, high load capacity, minimal maintenance, excellent precision and repeatability, and adaptability to various applications. Their compact design and ability to be customized make them suitable for both off-the-shelf and specialized equipment.

How do I choose the right linear slide manufacturer?

Select a manufacturer by first identifying your specific application needs—such as load, precision, environment, and standards. Consider factors like customization, lead times, engineering support, quality assurance, and after-sales service. Comparing manufacturer profiles and customer feedback can help you find a reliable partner that aligns with your project requirements.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services