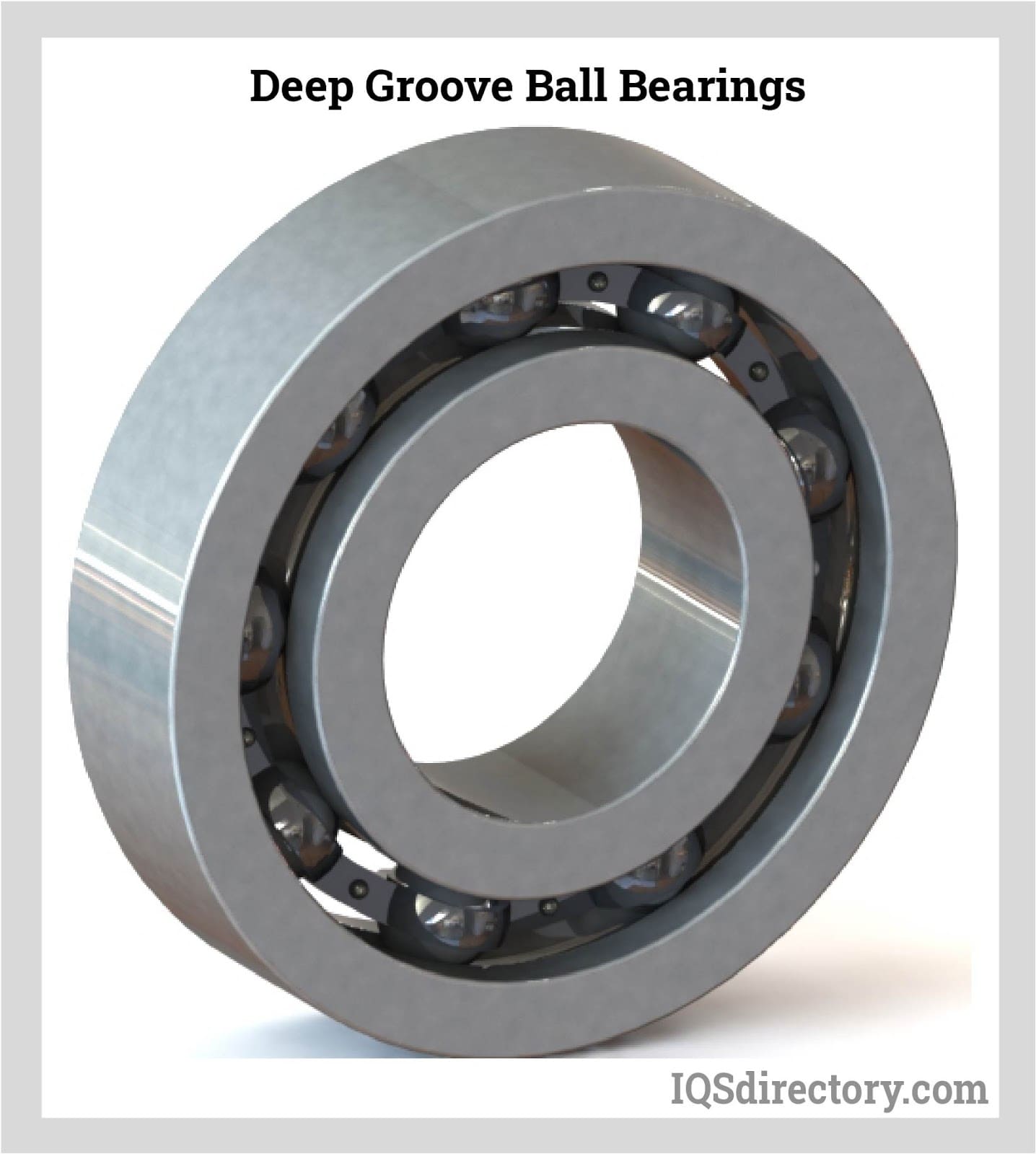

Ball bearing slides are a subcategory of linear slides used in areas where two surfaces move against each other to produce a very smooth and low-friction movement. The ball slides use metallic spheres made from durable materials like galvanized or regular steel and aluminum found in a confined rail system. Read More…

Del-Tron is a linear slide manufacturer/distributor of ball bearing slides, crossed roller tables, roller slides, multi-axis positioning stages, xy tables, motor-ready lead screw stages & crossed roller rail sets.

When describing Tusk Direct, a linear slide distributor, products such as linear motion components, roller tables, ball & crossed roller slides, dovetail slides, bushings, multi-axis positioners & motor ready lead screw actuators, come to mind.

Isotech is a distributor of precision linear motion components: air cylinders, linear actuators, linear slides, ball slide assemblies, crossed roller slide assemblies, re-circulating ball slide guides. We can supply standard or high precision products in either English or metric, all with the convenience of on-line ordering. Our parts are ready for installation right out of the box.

Established in 1967, Velmex makes manual & motor driven dovetail slides, open frame tables, twin rail slides, rotary and XY stages. Choose hand, lead screw or belt drive.

More Ball Bearing Slide Manufacturers

The moving component is attached to the rail system, and the balls enable smooth motion of the component.

Ball Bearing Slides: Comprehensive Guide, Features, Applications, and Supplier Selection

Ball bearing slides are critical linear motion components widely used in furniture, industrial automation, manufacturing, and robotics. By leveraging precision-engineered ball bearings, these linear slide rails enable drawers, cabinets, machinery, and specialized equipment to move smoothly and quietly, significantly reducing friction and wear over time. Whether you are searching for drawer slides for office furniture, linear motion guides for industrial applications, or exploring advanced soft-close mechanisms for kitchen cabinetry, understanding the fundamentals, variations, and decision factors of ball bearing slides is essential for optimal performance and longevity.

How do Ball Bearing Slides Function?

Ball bearing slides—also referred to as linear ball bearing slides or telescopic slides—are designed to reduce friction and facilitate smooth, controlled movement between two or more surfaces. The core mechanism involves free-rolling ball bearings that run within precision tracks or raceways, maintaining separation between moving parts and minimizing direct contact. This technology not only prevents damage to surfaces but also ensures consistent, effortless motion over thousands of cycles.

For example, in sliding drawers, the ball bearings roll along metallic tracks mounted between the desk or cabinet body and the drawer itself. This system prevents the two surfaces from rubbing directly against each other, ensuring the drawer glides open and closed without sticking, jamming, or producing excessive noise. In heavy-duty industrial environments, ball bearing linear slides are engineered to handle greater loads and higher duty cycles, making them ideal for machine tools, robotics, and automated production lines.

Upon reaching the endpoint of the drawer’s extension, an intermediate component (sometimes called a carriage or slider) allows for full extension until it cannot open any further. The interplay between the rails, intermediate members, and precision ball bearings defines the smoothness, durability, and weight capacity of the slide assembly.

Ball Bearing Slides Considerations

As a pivotal innovation in linear motion technology, ball bearing slides require careful evaluation to ensure optimal selection. The primary considerations when choosing ball bearing slides include:

- Load Capacity: Assess the total weight the slide must support, including both static and dynamic loads. Heavy-duty slides are engineered for industrial storage, server racks, and machinery, while light-duty options suit office drawers or home cabinetry.

- Travel Length & Extension: Determine whether you need full-extension (100% of drawer length), over-travel (beyond drawer length), or partial-extension slides. This is vital for accessibility and ergonomic design.

- Mounting Orientation: Consider side-mount, under-mount, or center-mount configurations based on application and aesthetic requirements.

- Durability & Cycle Life: High-quality ball bearing slides are rated for thousands—or even millions—of cycles, making them essential for high-use applications.

- Environment: For corrosive, humid, or food-safe environments, look for stainless steel ball bearing slides or those with specialized coatings.

- Noise Reduction: Soft-close and self-closing slides are popular in residential and commercial environments where noise minimization is a priority.

- Cost & Supplier Reputation: Price should be balanced with build quality, warranty, and the supplier’s technical support capabilities.

Choosing the wrong slide for your application can result in premature wear, sticking, jamming, or the need for costly furniture or equipment repairs. Always consult technical datasheets and, if needed, speak with a knowledgeable ball bearing slide distributor or manufacturer to match your requirements.

Types of Ball Bearing Slides

Ball bearing slides are available in several types, differentiated by their construction, mechanism, and application. Understanding these types is crucial for specifying the right slide for your project, whether it’s for furniture, industrial automation, medical equipment, or specialty machinery.

1. Ball Bearing Drawer Slide

Ball bearing drawer slides are the most widely used linear motion solutions for cabinetry, desks, and office furniture. These slides are composed of three main components: the cabinet (fixed) member, an intermediate (carriage) member, and the drawer (moving) member. Ball bearings positioned between these members allow for smooth, lateral movement with minimal friction.

The intermediate member interfaces with the ball bearings, providing stability and distributing load evenly. As the drawer opens, it glides over the ball bearings. Upon reaching full extension, the intermediate member itself slides further, enabling complete access to the drawer’s contents. This mechanism is ideal for both light-duty applications (such as office filing cabinets) and heavy-duty environments (like tool chests and industrial storage units).

Key Features:

- High load-bearing capacity for a range of applications

- Options for full-extension and over-extension

- Available in various lengths and mounting styles

- Engineered for smooth, quiet operation

- Compatible with locking mechanisms for secure storage

2. Soft Close Ball Bearing Slide

Soft close ball bearing slides represent the next generation of linear slide technology, providing a premium user experience. These slides incorporate a hydraulic or pneumatic damper, along with a spring-loaded mechanism, that automatically slows and closes the drawer quietly and gently—preventing slamming and minimizing wear on both the furniture and its contents.

The soft close system is typically equipped with a piston and spring (hydraulic system) that takes over as the drawer approaches the closed position. Even a gentle push initiates the soft-close action, allowing the drawer to finish closing silently and smoothly. This feature is especially popular in high-end kitchen cabinetry, office furniture, medical cabinets, and anywhere a premium, noise-free experience is valued.

Soft Close Slide Benefits:

- Enhanced user comfort and convenience

- Reduces noise and extends furniture life

- Prevents accidental slamming and damage to drawer contents

- Ideal for residential, commercial, and healthcare environments

- Available in various load ratings and lengths

3. Heavy-Duty Ball Bearing Slides

For applications demanding exceptional strength and reliability, heavy-duty ball bearing slides are engineered to support high loads (often exceeding 500 lbs or 225 kg) and withstand frequent use in industrial settings. Typical uses include server racks, industrial storage cabinets, toolboxes, and vehicle storage solutions.

Key Attributes:

- Robust construction with reinforced steel or stainless steel tracks

- Corrosion-resistant finishes for harsh environments

- Full-extension and over-extension options for complete access

- Lock-in/lock-out features for safety and convenience

- Engineered for high cycle life

4. Telescopic and Linear Ball Bearing Slides

Telescopic slides and linear ball bearing slides are specialized variants used where longer extension, high precision, or compact installation are required. Telescopic slides can extend well beyond their closed length, making them ideal for pull-out platforms, keyboard trays, and industrial automation modules.

Typical Applications:

- Laboratory equipment requiring precise positioning

- Machine guards and access panels in manufacturing lines

- Robotic arms and automation gantries

- Mobile medical and electronic equipment carts

- Architectural and stage equipment installations

Applications and Benefits of Ball Bearing Slides

Applications of Ball Bearing Slides

Ball bearing slides are indispensable across a wide spectrum of industries and products. Their versatility, reliability, and ease of integration make them the preferred linear motion solution for:

- Furniture & Cabinetry: Used in kitchen drawers, office desks, filing cabinets, and home storage solutions for smooth, quiet operation.

- Industrial Automation: Essential for machine tools, CNC equipment, packaging machines, and conveyor systems where precise, repeatable linear movement is required.

- Medical & Laboratory Equipment: Incorporated in medical carts, diagnostic devices, and laboratory drawers for hygienic, smooth, and reliable function.

- Robotics & Electronics: Enable precise movement in robotic arms, automation gantries, and electronic enclosure access panels.

- Automotive & Aerospace: Utilized in vehicle storage compartments, aircraft seating, and maintenance equipment where durability and vibration resistance are essential.

- Retail & Commercial Fixtures: Support display units, POS terminals, and secure storage systems in retail environments.

Benefits of Ball Bearing Slides

Investing in high-quality ball bearing slides delivers a range of advantages that translate to improved performance, reduced maintenance, and enhanced user satisfaction:

- Reduced Friction & Wear: Ball bearings minimize contact between moving parts, extending the life of furniture, equipment, and machinery.

- Smooth, Quiet Operation: Precision engineering ensures silent, effortless motion—ideal for noise-sensitive environments.

- Increased Load Capacity: Engineered to handle both light and heavy loads, supporting everything from delicate laboratory instruments to industrial storage systems.

- Low Maintenance: Self-lubricating options and corrosion-resistant finishes reduce the need for frequent servicing.

- Enhanced Safety: Soft-close, lock-in, and lock-out features help prevent accidental injury and protect valuable contents.

- Versatility: Available in a wide range of sizes, materials, and configurations to fit any application—from DIY home improvement to advanced industrial automation.

Common Questions About Ball Bearing Slides

- What are the differences between ball bearing slides and roller slides?

Ball bearing slides use spherical bearings to minimize friction and provide precise, smooth movement. Roller slides, in contrast, use cylindrical rollers, which are typically less precise and may not support as much weight or extend as far. - How do I choose the right load rating for my application?

Calculate the combined weight of the drawer and its contents. Add a safety margin (typically 25%), and select a slide with a rated load capacity above this total for optimal performance and longevity. - Are there ball bearing slides suitable for outdoor or corrosive environments?

Yes. Stainless steel ball bearing slides and those with specialized anti-corrosion coatings are available for marine, laboratory, and industrial outdoor use. - Can ball bearing slides be installed vertically?

While most slides are designed for horizontal installation, some heavy-duty or specialty slides can be mounted vertically for specific applications. Always check the manufacturer's guidelines for mounting options. - How do I maintain and lubricate ball bearing slides?

Most modern slides are self-lubricating or contain sealed bearings that require little to no maintenance. For high-use or harsh environments, periodic cleaning and lubrication with a suitable grease may be recommended. - What is the difference between full-extension and partial-extension slides?

Full-extension slides allow the drawer or platform to extend the entire length of the slide, providing complete access. Partial-extension slides only extend partway, which may be sufficient for lighter loads or less critical access.

Buyer’s Guide: How to Select the Best Ball Bearing Slides for Your Needs

When searching for the optimal ball bearing slide solution, consider the following factors to make the best purchase decision:

- Define Your Application: Is the slide for residential cabinetry, industrial machinery, medical equipment, or another use? The environment and load requirements will determine your options.

- Measure Required Travel: Calculate the extension needed for your drawer, panel, or moving component. Consider whether full or over-extension is necessary for accessibility.

- Determine Mounting Method: Choose between side-mount, under-mount, or center-mount based on space constraints and aesthetic preferences.

- Specify Load Capacity: Select a slide with a suitable load rating for your application, factoring in both the weight of the moving component and its contents.

- Consider Special Features: Do you require soft-close, self-closing, lock-in/lock-out, or corrosion-resistant features?

- Verify Quality and Compliance: Look for slides manufactured to recognized quality standards (e.g., ISO, RoHS) and supplied by reputable brands with documented performance and safety certifications.

- Consult Supplier Technical Support: If unsure, reach out to the supplier’s engineering team for advice and to request datasheets or CAD models for integration into your project.

Are you comparing ball bearing slide suppliers or manufacturers? Ask yourself:

- Which suppliers offer the best warranty and after-sales support?

- Do they provide comprehensive product documentation, CAD files, and technical support?

- Can they supply custom lengths, mounting options, or specialty finishes for your application?

Choosing the Correct Ball Bearing Slide Supplier

To ensure you achieve the most productive and cost-effective results when purchasing ball bearing slides, it is important to compare multiple suppliers. Here’s a step-by-step guide for selecting the right ball bearing slide supplier or distributor:

- Research and Shortlist: Use our ball bearing slides directory to identify reputable suppliers and manufacturers. Review each company’s business profile to understand their areas of expertise and capabilities.

- Request Quotes and Information: Use the contact forms provided on each supplier’s profile to request detailed product information, pricing, lead times, and custom options.

- Compare Technical Specifications: Review datasheets, load ratings, material types, and cycle life to ensure compatibility with your application.

- Evaluate Support and Services: Consider factors such as warranty, technical support, on-site assistance, and the ability to provide custom engineering solutions.

- Use Our RFQ Tool: Leverage our simple Request For Quote (RFQ) form to contact multiple ball bearing slide companies with the same inquiry, saving time and ensuring a competitive comparison.

- Preview Supplier Websites: Our patented website previewer allows you to quickly assess each supplier’s product range and specialties before making a final decision.

For large-scale projects, OEM manufacturing, or specialized requirements, establish a direct relationship with a trusted supplier who can provide ongoing support, inventory management, and design assistance.

Related Resources and Further Reading

- How to Install Ball Bearing Drawer Slides: Step-by-Step Guide

- Full Extension vs. Partial Extension Slides: Which Is Best?

- Heavy-Duty Linear Motion Solutions for Industry

- Soft Close Mechanisms Explained: Benefits and Applications

- Choosing Between Stainless Steel and Zinc-Plated Slides

Ready to Find the Best Ball Bearing Slides?

Whether you’re an engineer, furniture designer, facility manager, or home improvement enthusiast, choosing the right ball bearing slide is key to maximizing performance, durability, and user satisfaction. Start your search now by comparing top-rated ball bearing slide suppliers, reviewing product specifications, and requesting quotes for your specific needs. For personalized advice or technical support, reach out to our team or explore our comprehensive library of linear motion resources.

Have questions about selecting, installing, or troubleshooting ball bearing slides? Contact us today or browse our FAQ section to get expert guidance on your linear motion project.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services