This type of movement is useful in a wide variety of industrial applications where heavy objects need to be transported efficiently between locations. Usually linear motion guides are installed between machines or in areas were goods are constantly being moved. Read More…

Del-Tron is a linear slide manufacturer/distributor of ball bearing slides, crossed roller tables, roller slides, multi-axis positioning stages, xy tables, motor-ready lead screw stages & crossed roller rail sets.

When describing Tusk Direct, a linear slide distributor, products such as linear motion components, roller tables, ball & crossed roller slides, dovetail slides, bushings, multi-axis positioners & motor ready lead screw actuators, come to mind.

Isotech is a distributor of precision linear motion components: air cylinders, linear actuators, linear slides, ball slide assemblies, crossed roller slide assemblies, re-circulating ball slide guides. We can supply standard or high precision products in either English or metric, all with the convenience of on-line ordering. Our parts are ready for installation right out of the box.

Established in 1967, Velmex makes manual & motor driven dovetail slides, open frame tables, twin rail slides, rotary and XY stages. Choose hand, lead screw or belt drive.

More Linear Motion Guide Manufacturers

A linear motion guide can be powered by a motor or operated by hand to create movement. Various types of bearings or rolling parts can be used inside the linear motion guide to allow it to roll smoothly along the guide rail.

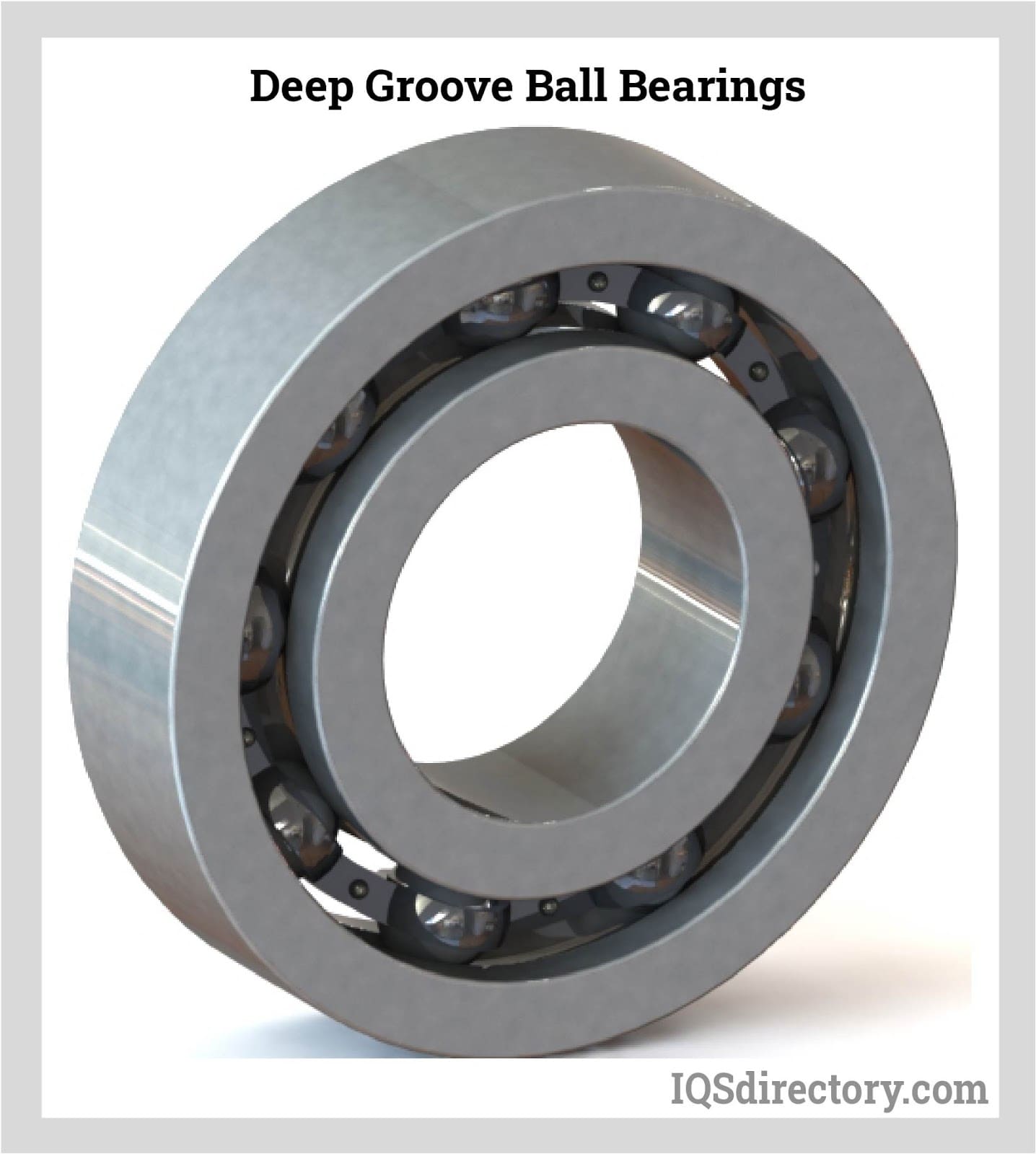

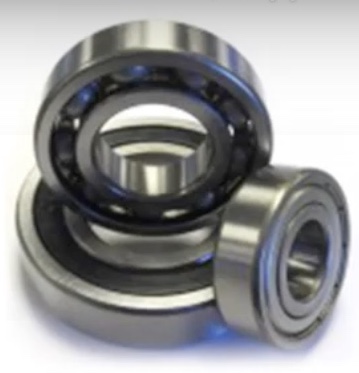

The different types of linear motion guide bearings include ball bearings, roller bearings, and magnetic bearings. Ball bearings are the most common type of rolling element for linear motion guides because they are both effective and affordable.

These small ball shaped components are placed in a sleeve or in a track between the two moving component of the guide and the rail. The moving component rolls over these bearings rather than making contact with the fixed portion of the slide which significantly reduces the amount of friction.

With reduced friction, the slide can move more smoothly. Roller bearings and magnetic bearings provide very similar benefits, but they operate in a slightly different way. Roller bearings mostly differ from ball bearings in their shape only.

Instead of a ball, they are flat cylinders and the sliding portion of the guide moves along the rounded edge of the cylinders. Magnetic bearings, on the other hand, differ more significantly from the other types of bearings.

This type of bearing consists of two encased magnets with opposite polarization. One is attached to the fixed portion of the linear guide and the other is attached to the sliding portion.

While the sliding portion is still incapable of coming off of the rail, the oppositely polarized magnets repel each other, keeping the two components from coming in physical contact with each other. This allows the sliding portion to move along the rail without experiencing significant frictional forces.

Linear motion guides are used in all kinds of household and industrial applications. Most sliding doors in a house or desk drawers in an office use some kind of linear motion guide to allow someone to smoothly slide them open or close them back up.

Conveyor belts in some automated factory assembly lines also use linear motion guides to keep new products moving down the assembly line and on to the next step in production. In industrial or household settings, linear motion systems help to make tasks easier and more efficient every day.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services