Linear slides play a very important role in today’s industries, serving clean room operating systems, robotic assembly machinery, automatic packaging equipment and CNC machining equipment. Precision eyeglass assembly, instrumentation and specialized processes are also able to take advantage of this product. Linear slides are used to provide motion to machinery or other objects along a single axis. Some newer models are able to move along multiple axes, but the idea is the same, to move objects from one point to another more easily. The average linear slide is composed of a stationary base, a carriage or platform and a linear rail of bearings. The carriage is able to move back and forth, sliding along the bearings. The base provides the mechanism with a very strict range of motion to create a motion in a very distinct pattern or direction.

When choosing the linear slide for your application, the working environment is probably one of the most important factors. Cast iron, aluminum and stainless steel are popular material options due to their strength and durability. Stainless steel provides the added benefit of being corrosion resistant. Protective housing may also be added to the systems to prevent dust or debris from interfering with the process. Exposure to these items can increase the wear on both the ball bearings and the slides, making the machine run less efficiently.

Air Cylinders

Air Cylinders Assembly Machinery

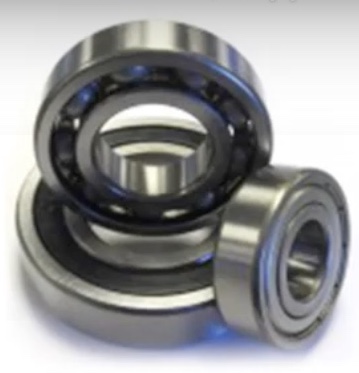

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services