XY tables, often referred to as XY stages, cross-working tables, or coordinate tables, are motorized linear slides with linear motion based on bearings and are driven by an external drive device, most frequently a linear motor. XY tables, as their name suggests, have two axes (X and Y) positioned on top of one another, and their normal stroke length is one meter or fewer. High-performance placement along many axes is made possible by the construction and configuration of XY tables. Read More…

Del-Tron is a linear slide manufacturer/distributor of ball bearing slides, crossed roller tables, roller slides, multi-axis positioning stages, xy tables, motor-ready lead screw stages & crossed roller rail sets.

When describing Tusk Direct, a linear slide distributor, products such as linear motion components, roller tables, ball & crossed roller slides, dovetail slides, bushings, multi-axis positioners & motor ready lead screw actuators, come to mind.

Isotech is a distributor of precision linear motion components: air cylinders, linear actuators, linear slides, ball slide assemblies, crossed roller slide assemblies, re-circulating ball slide guides. We can supply standard or high precision products in either English or metric, all with the convenience of on-line ordering. Our parts are ready for installation right out of the box.

More XY Table Manufacturers

Construction of XY Tables

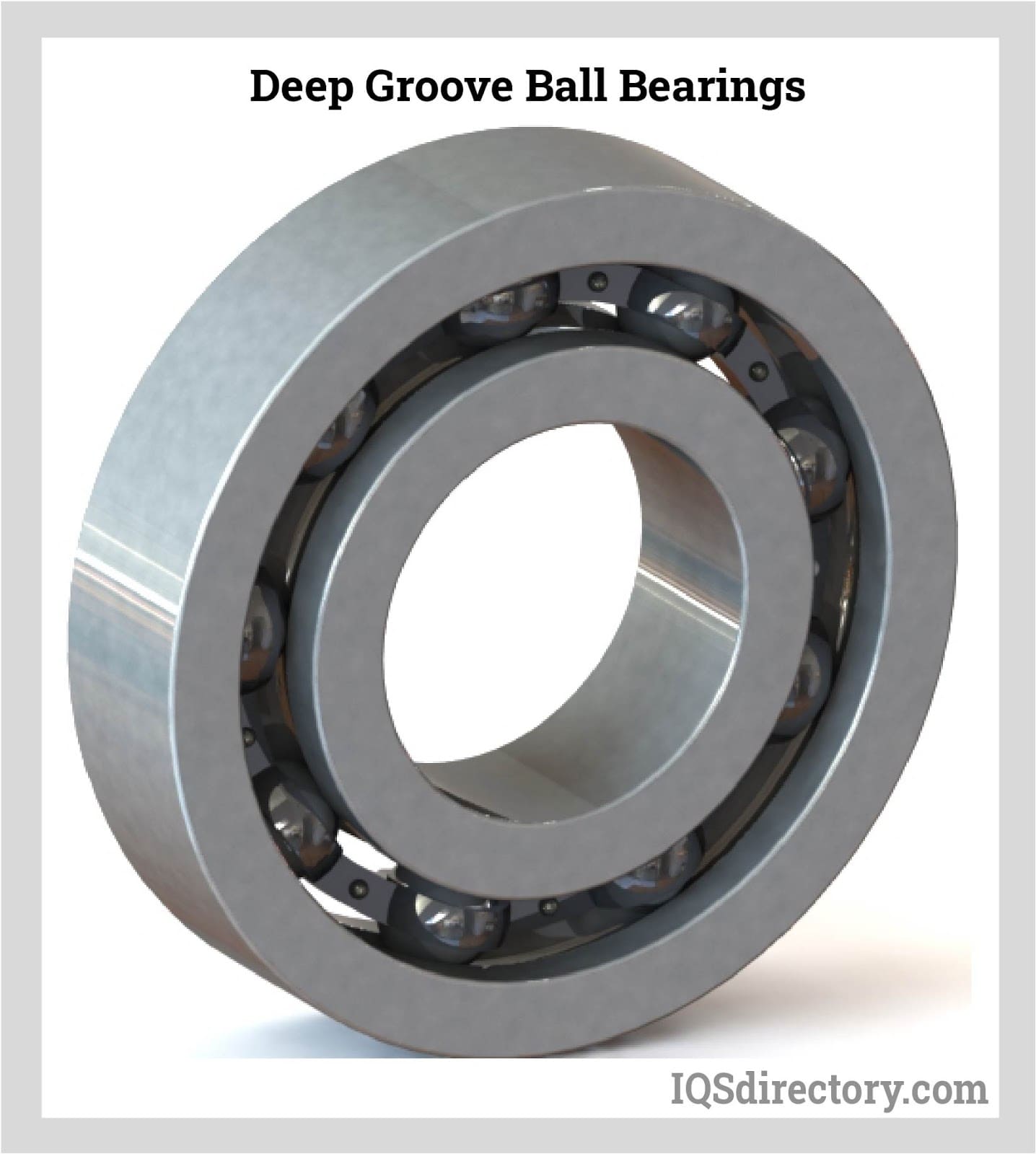

XY tables are made up of forcers and platens and have flat surfaces mounted on Ball bearing slides or roller slides with numerous linear bases. The former slides continuously and linearly across the platen while gliding over it on frictionless air bearings. To generate numerous axes, linear bases are frequently stacked on top of one another, with the top "Y" axis as the base that supports the table and a carriage to the bottom base. On both axes, adjustable gibs can be added. Stainless steel, cast iron, bronze for the bearings, and aluminum for the frames are used to make XY tables.

Variations of XY Tables

The design and construction of the XY tables and the actuator or drive mechanism are employed to determine how differently they can be applied.

Planar XY Table With Air Bearings

By definition, a shared reference plane is used for both X and Y-axis motion in planar XY-tables. The planar air-bearing XY tables are employed when high precision is required in the smoothness of motion, constant velocity, straightness, and flatness. As a result, they have a very high performance. Planar XY air-bearing stages design incorporates a shared foundation for X and Y motion. Linear motors power air-bearing XY stages. Additionally, they are noted for offering high acceleration and velocity, which are essential qualities for a typical manufacturing application for XY tables.

Miniature XY Tables

The design of a miniature XY table must take additional factors into account because of their small and compact form. These small tables are built using unique design, fabrication, and manufacturing processes. Miniature tables are the most exact XY table variations available. Hence extra consideration is given to their design and development to ensure optimal performance and efficiency.

Due to the electronics and sensors built into the machine's structure, the automatic motorized versions are even more accurate and precise. In addition, the positioning of the platform is managed by specialized micro servo/stepper motors. As a result, these small XY tables have extremely high resolution, accuracy, speed, acceleration, and precision.

Stacked XY Tables

Depending on the application requirements, XY motion can be produced by stacking two linear stages with comparable strokes or types. The modular structure offers versatility. The disadvantage is that, for long travel ranges, the lack of support for the base of the upper axis causes flatness and pitch/roll errors to rise toward the end of travel.

Gantry XY Tables

Another type of stacked stage design is an XY table in the gantry style. When heavier weights need to be moved over longer XY travel distances or when a stationary workpiece needs to be scanned or processed from above, gantry XY tables are frequently used. For optimum performance and to prevent binding, a motion controller with a unique gantry control algorithm is needed. In laser processing, imaging, and metrology applications, gantry XY tables are frequently utilized. They are available in a wide range and frequently constructed on a granite base for extra high stability and precision.

Open Frame XY Tables

As the name implies, this is a specific XY table with an open frame. The open frame XY stages are specifically made to offer great accuracy in a small package. Therefore, transmitted light applications are well suited for the open-frame XY stages.

Applications of XY Tables

- Pharmaceutical, manufacturing, semiconductor, and other industries that require automatic movement in their construction processes use XY tables in various mechanical processes.

- Material handling and manufacturing of machinery in mechanical engineering also make use of XY tables.

- While their bases are stationary, robotic arms and other automated machines have a restricted range of motion; however, XY tables enable these bases to move horizontally in the X and Y axes.

Benefits of XY Tables

- Higher Accuracy: XY tables are considered highly accurate and simple to use, and they don't need a lot of upkeep.

- Greater Effectiveness: XY tables offer higher productivity in manufacturing businesses since they are precise.

- Consistent Work Quality: One can move the pieces quickly and reach the proper locations using XY tables.

- High Precision Work: XY tables with precise wheels are required for high-precision work. In a way that other tools are just unable to, XY tables can accurately direct movement.

- Adjustable Travel Range: XY tables can have an adjustable range despite their small size. This fact indicates that the travel range can be adjusted to allow work on even some of the largest workshop objects.

Selecting the Correct XY Table Supplier

To ensure you have the most positive outcome when purchasing XY tables from an XY table supplier, it is important to compare several companies using our directory of XY table suppliers. Each XY table supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each XY table business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple XY table companies with the same form.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services